When it comes to training operators on proper usage and maintenance techniques, it is crucial to ensure that all individuals are equipped with the knowledge and skills necessary to perform their tasks effectively. Proper training not only enhances productivity but also ensures the safety of both equipment and personnel.

Operators should be trained on how to use equipment correctly, including understanding its functions and limitations. This will help prevent accidents and costly damage to machinery. Additionally, operators should be educated on maintenance techniques to keep equipment in optimal working condition. Regular maintenance can prolong the lifespan of equipment and reduce the likelihood of breakdowns.

Training should be conducted by experienced professionals who can provide practical demonstrations and hands-on practice. This allows operators to learn through experience and gain a better understanding of the equipment they are working with. It is important for trainers to emphasize the importance of following safety protocols and using personal protective equipment at all times.

Overall, training operators on proper usage and maintenance techniques is essential for ensuring smooth operations and preventing unnecessary downtime. By investing in comprehensive training programs, companies can improve efficiency, reduce costs, and create a safe work environment for all employees.

When it comes to training operators on proper usage and maintenance techniques, safety precautions should always be a top priority. Ensuring that operators are well-informed and properly trained is essential in preventing accidents and injuries in the workplace.

One of the most important safety precautions to consider when training operators is the use of personal protective equipment (PPE). This includes items such as gloves, goggles, helmets, and ear protection. Operators should be instructed on how to properly wear and use their PPE to ensure maximum protection.

Additionally, operators should be trained on proper lifting techniques to prevent strain or injury. This includes bending at the knees, keeping the back straight, and using mechanical aids when necessary. Proper ergonomics should also be emphasized to reduce the risk of musculoskeletal disorders.

Proper maintenance techniques are also crucial in ensuring operator safety. Operators should be trained on how to inspect equipment for signs of wear or damage, as well as how to perform routine maintenance tasks. Regular maintenance not only prolongs the life of equipment but also reduces the likelihood of malfunctions or breakdowns.

Lastly, operators should be educated on emergency procedures in case of an accident or malfunction. This includes knowing how to safely shut down equipment, evacuate the area if necessary, and contact emergency services if needed.

By implementing these safety precautions into operator training programs, companies can help ensure a safe and productive work environment for all employees. Remember - safety always comes first!

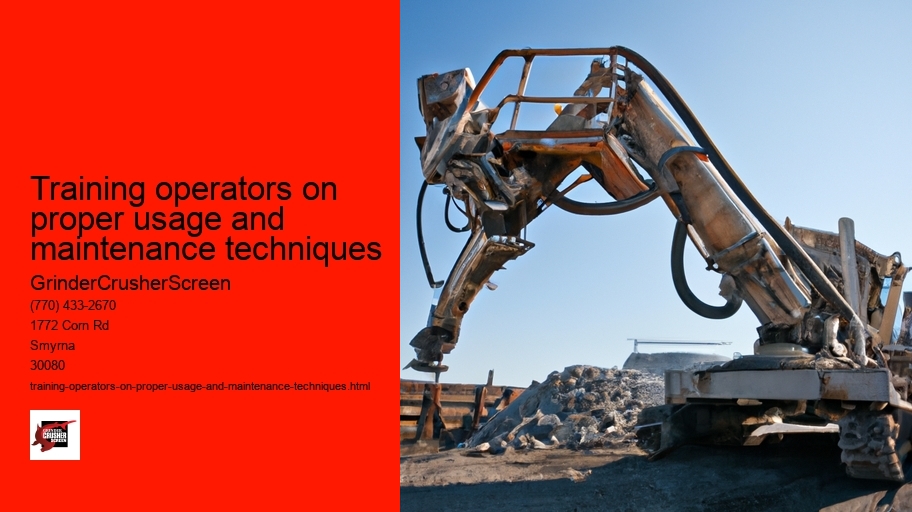

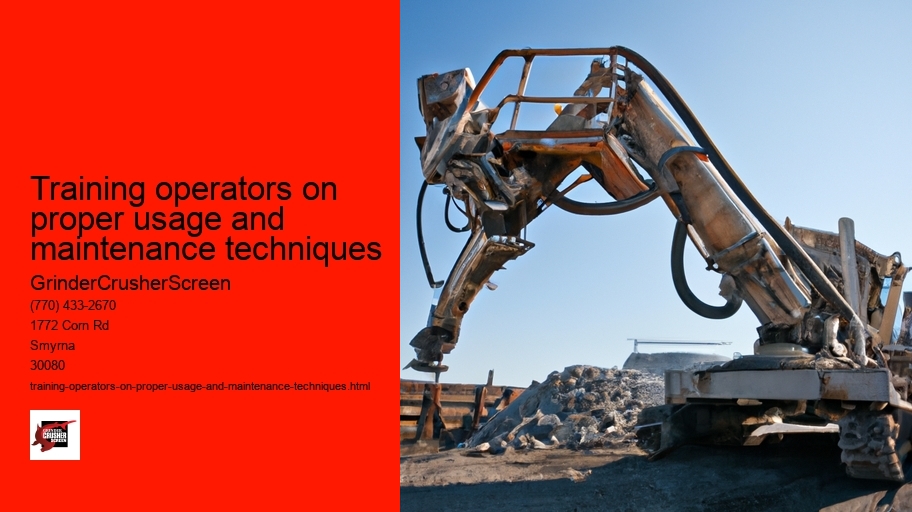

When it comes to the concrete recycling industry, finding dependable, long-lasting, and efficient equipment is essential for optimal performance. GrinderCrusherScreen is your go-to source for high-performance concrete crushers for sale, providing a range of options designed to satisfy the most challenging project requirements. Whether you’re working in building, tear-down projects, or aggregate processing, owning the right crusher equipment can dramatically enhance productivity and optimize your operations.

At GrinderCrusherScreen, we understand that every job is unique. That’s why we offer a broad range of concrete crushers for sale, suited for different materials, capacity requirements, and working environments. Our equipment is built to provide enduring results while reducing interruptions and maintenance costs.

The concrete crushers for sale at GrinderCrusherScreen are built for accuracy and efficiency. By leveraging modern engineering and innovative design features, our crushers ensure that your recycling process is both rapid and complete. With high-powered hydraulic systems and strong crushing jaws, you can break down large concrete blocks, sections, and waste into smaller pieces quickly and safely.

Our selection of concrete crushers is not only ideal for on-site demolition projects but also ideal for recycling concrete materials into aggregate for new projects. Whether you need to crush compact sections of concrete or larger structures, our crushers are adaptable enough to handle a range of operations. The ability to produce crushed concrete of varying sizes makes them crucial for contractors in need of dependable material for road construction, outdoor projects, and more.

Durability is a crucial factor in any robust equipment, and the concrete crushers for sale at GrinderCrusherScreen are no different. Constructed with high-quality steel and reinforced components, these crushers can endure the most demanding environments without sacrificing performance. This extended lifespan ensures that your purchase will deliver significant value for the long term to come.

Reusing concrete on-site has become a critical practice within the building and deconstruction industries. It minimizes the demand for hauling raw materials and dumping of concrete waste, which in turn cuts down on expenses and ecological footprints. By employing our concrete crushers for sale, companies can streamline their processes, enhance project efficiency, and contribute to eco-friendly strategies.

Concrete crushers enable the recycling of used material into usable aggregate, which can be sold again or reused for future construction projects. This lowers the cost associated with acquiring fresh materials while reducing logistics and disposal fees. Based on industry experts, recycling concrete on-site can result in up to 30% savings compared to using virgin materials.

Environmental responsibility is a rising priority across all industries, and construction is no exception. Repurposing concrete through the utilization of crushers significantly reduces the need for new materials, thus conserving natural resources. Additionally, it reduces carbon emissions from transporting waste to landfills. The concrete crushers for sale at Grinder Crusher Screen align with modern environmental regulations, helping your company meet sustainability goals while maximizing performance.

Efficiency is key in the construction world, and concrete crushers can help you save both. On-site concrete crushing removes the requirement for hauling to recycling plants, meaning that the output can be converted and deployed instantly. This accelerates the project schedule and ensures that resources are always on hand for any phase of the operation.

Concrete crushers come in various models, each designed for particular tasks. At Grinder Crusher Screen, we take pride in offering a broad range of crushers, guaranteeing that you get the ideal machine for your project’s requirements.

Jaw crushers are recognized for their strong crushing action and versatility. These crushers are suited for reducing heavier concrete blocks into more manageable pieces. The jaw crushers for sale at GrinderCrusherScreen are built for high capacity and performance, making them perfect for construction professionals who need reliable output.

For jobs that require finer material output, impact crushers are the preferred choice. These crushers use modern technology to break down concrete into precise sizes, ideal for specific applications such as road construction or landscaping. The impact crushers for sale at GrinderCrusherScreen are designed to provide optimal performance, reduce energy consumption, and simplified maintenance.

Cone crushers are well-suited for secondary or tertiary crushing stages. These machines offer top-tier crushing capabilities for smaller, more precise pieces. Whether you’re handling reinforced concrete or other hard materials, cone crushers from GrinderCrusherScreen will provide reliable and top-notch results.

Selecting the right concrete crusher for sale is vital to guaranteeing the success of your project. There are several important elements to take into account when making your decision:

Understanding the type of material you’re dealing with is crucial. Different crushers excel with different material sizes and durability. Different crushers excel with different material sizes and hardness levels. For example, jaw crushers are ideal for larger, harder materials, while impact crushers work well with more refined, softer materials.

Each project has different production needs, and choosing a crusher that fits your required capacity will maximize efficiency. Evaluate how much material needs to be processed per day and whether the crusher can meet those demands without constant maintenance or downtime.

For contractors working on multiple sites, a portable concrete crusher is a valuable asset. At Grinder Crusher Screen, we offer a range of mobile concrete crushers for sale, enabling you to move equipment seamlessly between job sites and lower transportation costs.

Grinder Crusher Screen has proven itself as a leader in the recycling equipment industry by providing top-tier products backed by superior customer service. Our team of experts is here to guide you through the entire process—from selecting the right concrete crusher for sale to providing maintenance tips and technical support. Here’s why you should rely on us for your concrete crushing needs:

With decades of experience in the recycling equipment industry, we comprehend the unique challenges of concrete crushing and can recommend the best solutions for your needs.

At Grinder Crusher Screen, we believe that our relationship with our customers extends at the point of sale. Our knowledgeable staff is always ready to assist with any queries or concerns, ensuring that your equipment performs at optimal performance.

Our catalog of concrete crushers for sale features options for every size and scope of project. Whether you need a small crusher for tight spaces or a heavy-duty model for big crushing jobs, we’ve got what you need.

When it comes to finding the best concrete crushers for sale, GrinderCrusherScreen provides an unmatched combination of quality, durability, and performance. By choosing from our wide selection of crushers, you’ll be spending in equipment that boosts productivity, reduces costs, and aligns with modern sustainability practices. Explore our vast range of concrete crushers for sale today and see why so many construction experts trust GrinderCrusherScreen to deliver the best in recycling equipment.

Proper maintenance procedures are essential when it comes to training operators on using and maintaining equipment. It is crucial that operators understand how to operate machinery correctly in order to prevent accidents and ensure the equipment's longevity.

During training sessions, operators should be taught how to properly use the equipment, including safety precautions and best practices for operation. This includes understanding the various components of the machinery and how they function together, as well as how to perform basic maintenance tasks such as cleaning and lubricating.

In addition to operating procedures, operators should also be trained on proper maintenance techniques. This includes regular inspections to check for any signs of wear or damage, as well as scheduled maintenance tasks such as changing filters or oil. By staying on top of these tasks, operators can help prevent costly breakdowns and extend the life of the equipment.

It is important for operators to receive ongoing training and support in order to stay up-to-date on proper usage and maintenance techniques. By investing in training programs, companies can ensure that their operators are knowledgeable and skilled in operating equipment safely and efficiently.

Overall, proper maintenance procedures play a vital role in ensuring that equipment operates smoothly and safely. By training operators on proper usage and maintenance techniques, companies can protect their investments and improve overall productivity.

When it comes to training operators on proper usage and maintenance techniques, troubleshooting common issues is a crucial aspect that cannot be overlooked. Ensuring that operators are equipped with the knowledge and skills to address any potential problems that may arise is essential for the smooth operation of equipment and machinery.

One common issue that operators may face is a lack of understanding of the proper usage of equipment. This can lead to inefficient operation, increased wear and tear on machinery, and potentially dangerous situations. By providing thorough training on how to properly use equipment, operators can avoid these issues and ensure that they are operating in a safe and effective manner.

Another common issue that operators may encounter is a lack of maintenance knowledge. Regular maintenance is key to ensuring the longevity and efficiency of equipment, but if operators are not trained on how to properly maintain machinery, problems can quickly arise. By teaching operators how to perform routine maintenance tasks, such as lubrication or cleaning, they can prevent issues before they escalate into more serious problems.

In the event that an issue does occur, it is important for operators to be able to troubleshoot and address the problem effectively. This requires a solid understanding of the equipment they are working with, as well as critical thinking skills to identify and resolve issues in a timely manner. By providing hands-on training and guidance on troubleshooting techniques, operators can confidently handle any issues that may arise during operation.

Overall, troubleshooting common issues is an essential component of training operators on proper usage and maintenance techniques. By equipping operators with the knowledge and skills needed to address problems effectively, organizations can ensure smooth operations, increase efficiency, and maximize the lifespan of their equipment.

When it comes to training operators on proper usage and maintenance techniques, one important aspect to focus on is cleaning and storage guidelines. Ensuring that equipment is kept clean and stored correctly can greatly impact its performance and lifespan.

Operators should be educated on the importance of regularly cleaning equipment after use. This not only helps maintain hygiene standards but also prevents the build-up of dirt or debris that could potentially cause damage or malfunctions. Providing specific instructions on how to properly clean each piece of equipment is essential to ensure thorough cleaning.

In addition to cleaning, proper storage is crucial in maintaining equipment in good condition. Operators should be informed about the best practices for storing equipment when not in use. This includes keeping tools in a dry and secure location, away from extreme temperatures or moisture that could cause rust or corrosion.

By emphasizing the significance of cleaning and storage guidelines during operator training, businesses can prolong the life of their equipment and reduce the likelihood of costly repairs or replacements. Ultimately, investing time in educating operators on these practices will lead to more efficient operations and improved overall productivity.

Regular inspections are crucial when it comes to training operators on proper usage and maintenance techniques. These inspections ensure that equipment is being used correctly and maintained properly, which in turn can help prevent costly breakdowns and accidents.

By conducting regular inspections, operators can identify any issues or potential problems early on, allowing them to address these issues before they escalate into larger problems. This proactive approach not only helps to extend the lifespan of the equipment but also ensures that it continues to operate safely and efficiently.

Furthermore, regular inspections provide an opportunity for operators to receive feedback on their performance and make any necessary adjustments to their techniques. This feedback can help improve operator skills and knowledge, ultimately leading to better overall performance.

In conclusion, regular inspections play a vital role in training operators on proper equipment usage and maintenance techniques. By prioritizing these inspections, companies can ensure that their equipment is being used safely and effectively, ultimately leading to improved productivity and reduced downtime.